Roeslein & Associates, Inc. is currently prepping for the largest tradeshow in the metal packaging industry, METPACK 2023. Every three years, market leaders and specialized companies from the metal packaging industry present their innovations at this week-long extravaganza in Essen, Germany. This year, the show will take place May 2nd – 6th. Roeslein & Associates will be sending 15 representatives from the company who will participate in the show; Roeslein will be located in Hall 3.0, booth 3D49.

Focusing on LEAN Manufacturing – From Employee Knowledge to Product Configuration

Roeslein received a grant for a full day of lean training for 20 employees led by IMEC. This interactive workshop combined comprehensive classroom instruction with the simulation of a production facility. IMEC specialists introduced the basic concepts of lean manufacturing to the Roeslein team and demonstrated the tools and methodologies necessary to implement lean effectively in operations.

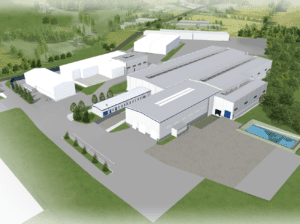

Roeslein Poland Opens Doors to New Facility

Rendering of new facility

In 2019, Roeslein & Associates acquired MCS Technology and rebranded the operation as its Roeslein Poland facility. At the same time, the company purchased 12 acres of land to develop. After several years, construction, renovations, and expansions are complete, and a new manufacturing facility is ready to be unveiled.

The renovations to the current facilities will allow Roeslein’s Poland team to better organize its departments and workflow, as well as allow an increase in production capacity and the manufacturing of larger modules. Each department will also have dedicated areas to improve efficiency and streamline operations for a quicker output of units, leading to reduced project times.

Bringing New Technology to Market: UV LED & Power Supply Upgrade

Roeslein & Associates is bringing new technology to market by transforming its proprietary Ultra Violet Bottom Coating System (UVBC) with a reliable, sustainable, and proven UV LED curing and control system update.

As an alternative to microwave and arc lamp technology, the UV LED technology leads to increased reliability and efficiency, lower power consumption, and an increased 70,000+ hour lamp life. The UV lamp and power supplies are smaller, lighter, less expensive, and provide better availability for purchase. With regard to coatings, a new coating has been implemented for LED curing and vetted by a third party for validation.

Roeslein & Associates, Inc. Acquires Method Flow Products, LLC.

Roeslein & Associates has acquired Method Flow Products, LLC, a provider of oil and gas measurement and automation products, services, and distribution systems as of March 31, 2023. Method Flow Products is headquartered out of Evans, Colorado, and regionally located across the United States to fully support major customers in the oil & gas market.

“Welcoming Method Flow into the Roeslein family of brands helps us push forward on meeting our strategic goal to diversify our business into new markets and to expand the application of our prefabricated and preassembled modular systems into new industries,” said Roeslein President and COO Brian Sneed. “One of the most exciting parts of this acquisition is the strategic value that Roeslein & Associates, Inc., Servtech, and Method Flow Products will deliver to our customers.”

Martha Rojas to Join Roeslein & Associates, Inc.

Roeslein & Associates, Inc. is pleased to appoint Ms. Martha Rojas as Global Business Development Executive. Ms. Rojas has a tenure of professional management expertise in the numerous aspects of global shipping and logistics. Roeslein is thrilled to announce that Martha will join the Roeslein team as it closes out celebrating Women’s History Month in conjunction with Women in Construction week, celebrated March 5-11, and International Day of the Woman on March 8. Being a true industry icon, serving the international can manufacturing industry for thirty-plus years, Martha will be a welcomed and well-aligned member of Roeslein’s global sales team.

Updating Conveyance Technology to Meet Market Demand

During the pandemic, the container manufacturing industry saw skyrocketing sales. Consumers were spending, increasing the demand for production and the types of products in creation. The market was forced to continue to diversify with size changes as consumers preferred sleek cans to transitional cans. Additionally, many customers were requesting greenfield facilities, line additions, facility expansions, and line speed-ups. “The demand for aluminum beverage cans was reaching unprecedented levels. We have been working the past five years toward our strategic growth plan to ensure that we are able to continue to keep pace and provide world-class services and products to our customers,” said Brian Sneed, President & COO of Roeslein & Associates, Inc., parent company to Pride Conveyance Systems. These measures have included expanding its regional footprint, increasing its manufacturing space, and continuously recruiting top talent in professional services.

Roeslein Michigan City Celebrates Safety Milestone

Roeslein & Associates recently celebrated a safety milestone at their manufacturing plant in Michigan City, Indiana. As of November 17th, 2022, Roeslein Michigan City has had 717 days without a lost time injury. They celebrated this milestone by hosting an employee luncheon with members of the Leadership and Safety teams.

“This achievement demonstrates our culture and commitment to ensuring everyone goes home to their loved ones the same way they walked through the door at the start of their shift,” said RMC Operations Manager Alex Strelinski. “I believe that safety is the foundation in all that we do here at Roeslein, and I would like to personally thank our entire team for all of their hard work and dedication to those core values.”

Roeslein Poland Undergoes Full-Scale Renovation & Expansion

Roeslein Poland is undergoing a full-scale renovation and expansion of its facilities to accommodate the company’s rapid growth and meet customer demand.

Roeslein Recognized on the List of St. Louis’s Top Privately Held Companies

On Thursday, October 13th, 2022, Roeslein & Associates Inc. was recognized by the St. Louis Business Journal as one of the Top 150 Privately Held Companies in the area. The St. Louis Business Journal’s Top Companies event celebrates the region’s largest and fastest-growing companies that have had the largest increase in revenue for the previous fiscal year. Roeslein placed #36 on the list.

- « Previous Page

- 1

- 2

- 3

- 4

- 5

- …

- 29

- Next Page »